See How Maker's Mark Crafts Its Beloved Bourbon [PHOTOS]

Welcome to Maker's Mark. The distillery is in Loretto, Kentucky, about an hour and a half from Louisville and the same distance from Lexington.

![See How Maker's Mark Crafts Its Beloved Bourbon [PHOTOS]](/_next/image?url=https%3A%2F%2Fstaticbiassets.in%2Fthumb%2Fmsid-21139981%2Cwidth-700%2Cheight-525%2Cimgsize-777589%2Fwelcome-to-makers-mark-the-distillery-is-in-loretto-kentucky-about-an-hour-and-a-half-from-louisville-and-the-same-distance-from-lexington-.jpg&w=3840&q=75)

The property was once the site of Burks' Distillery, which Bill Samuels Sr. bought in 1954. The business soon became a family affair, with Samuels' wife Marge baking breads to test various grain combinations used in whisky and developing the signature packaging.

Bill Jr., an engineer, eventually joined the family business after working as a rocket scientist. An engineer with a sense of humor, he designed this covered footbridge without a single right angle, according to Master Distiller Greg Davis.

Maker's is a functioning distillery with around 100 employees, but touches of history are everywhere. This old-school fire truck is apparently still functional, but we hope no one's counting on it.

This creek once powered the entire plant. But once electricity arrived, the water wheel was removed and the creek was redirected around the distillery.

All of the ingredients in Maker's Mark bourbon, including corn and soft red winter wheat, are deposited at this silo. All the ingredients are grown within 100 miles of the distillery.

We expected to find a major commercial operation but the actual distillery is relatively small. It produces a little over a million cases of bourbon a year.

The first thing that hits visitors is the smell: there's a sharp aroma of warm, yeasty bread. Maker's Mark has its own strain of yeast, which it has kept alive for decades.

The grains are all ground by a crushing machine. After they're crushed, the corn is brought to a boil and the wheat is added. Once the mixture cools, malted barley is added to break down the enzymes.

The mash is then sent to ferment in one of eight gigantic cypress fermenters. After around 12 hours, the solids rise and the mash starts to bubble as carbon dioxide is released.

As it ferments, the mash becomes sour. It starts to smell sour too, but not in a rotten way.

Once the fermentation process is complete, the mash is distilled twice; once through a beer still and again through a second still.

After the second distillation, the liquid is 140 proof. We tasted it, and while we've never had moonshine, we can imagine this is what it would taste like. Fittingly, at this point in the process, it's called "white dog."

But for some employees, tasting un-aged liquor is just part of the job. At the quality control lab, a 20-person tasting panel tests every batch for consistency.

Tasters sniff the "white dog," then swirl it and sip it to make sure there's nothing off about it before it's sent to be barreled.

Finished products are tested as well. If you're lucky (like we were) someone on the tasting panel has also come up with a tasty bourbon concoction—in this case, "Apple Pie."

After distillation, the spirit is pumped to the cooperage plant to go into barrels. The barrels, made of aged white oak and charred on the inside, are inspected to make sure there are no cracks or flaws.

The char, which Davis likened to "the belly of an alligator," ensures that sugar from the wood gradually seeps into the bourbon during the aging process.

The "bung" of each barrel is hammered in by hand. Once barrels are filled, they are sent to a warehouse, where they'll spend at least 3 summers on the warmer top floors, and several more years on the cooler lower floors.

There's no magic formula for how long it takes bourbon to age. Depending on how long and hot the summers are, Maker's Mark ages for between 5.5 and 7 years.

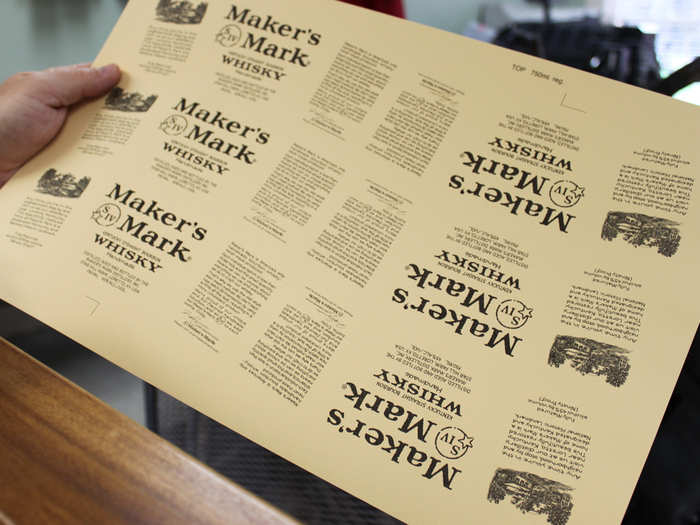

Over in the bottling plant, Maker's Mark labels are printed in thick sheets on two antiquated printing presses.

And a hand-operated cutting machine is used to stamp out labels.

In addition to coming up with the wax seals, Marge Samuels also had the idea to make the labels look hand torn.

Once the aging process is complete, 150 barrels are combined into a batch, ensuring consistency in the taste of Maker's Mark. Bottles are unboxed and placed on a conveyor belt.

Bottles are rinsed out with a splash of Maker's Mark, ensuring that nothing touches the inside of the glass except pure bourbon.

A machine fills bottles and seals them with a cap. It's one part of the process that has been mechanized.

But the signature red wax seal is dipped by hand. Four women dip the tops into steaming vats of melted red wax, 72,000 a day.

If the wax drips onto the label, the bottle is rejected. The red wax seal is trademarked.

After a brief trip through a cooler, the bottles are ready to be packaged.

The plant bottles 1.1 million cases a year, which sell in all 50 states and internationally. New York, California, and Texas are the biggest markets for Maker's Mark.

Of course, if you're going to travel to Loretto, Kentucky, you're going to want to do more than watch bourbon flow through a still.

There are also tours and tastings; the distillery is one of six on the Kentucky Bourbon Trail, and a popular destination for bachelor parties.

Maker's Mark is currently building out a bigger tasting room to accommodate all its visitors.

Visitors can also try their hand dipping a bottle into wax; it's harder than it looks to get it right.

Of course, you can always have a professional help you out.

History buffs will be impressed to learn that the country's oldest package liquor store sits on Maker's Marks grounds. The high windows let cars pull right up to get a refill.

The liquor doesn't flow quite so freely anymore.

There's also a restored historic house, where events are held.

It may not be the most efficient way to make a beverage, but if you're a bourbon drinker, the end results are sure to please.

Popular Right Now

Popular Keywords

Advertisement