See inside the cutting-edge new factory where Ford will build the electric F-150 Lightning

Tim Levin

Ford Rouge Electric Vehicle Center.Tim Levin/Insider

- Ford's first electric pickup, the F-150 Lightning, is coming in spring 2022.

- The Blue Oval is building a brand-new facility to assemble the EV in Dearborn, Michigan.

- The plant is packed with new tech like autonomous vehicle carriers, robots, and charging plugs.

Ford is almost done building out a brand-new, state-of-the-art plant where it will assemble the electric F-150 Lightning.

The Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

The Blue Oval is still putting the finishing touches on the facility, but I got an early look inside.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

The clean-sheet Rouge Electric Vehicle Center comes as part of Ford's $700 million investment in its Rouge Complex, where it also manufactures gas-powered F-Series trucks.

Ford Rouge Electric Vehicle Center Rendering

Ford

The 500,000-square-foot plant will start pumping out F-150 Lightnings closer to the EV's official delivery date of spring 2022.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

For now, Ford is testing out equipment and fine-tuning the manufacturing process.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

The truck's frame and body will get built nearby, and its battery packs will come from another yet-to-be-announced location. This shiny new building is where all those parts will come together into F-150 Lightnings.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

F-150 cabs and pickup beds will arrive by conveyor belt with a fresh coat of paint.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

From there, they'll make their way to different stations where workers will add on all the interior and exterior bits that turn these hunks of metal into working trucks.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

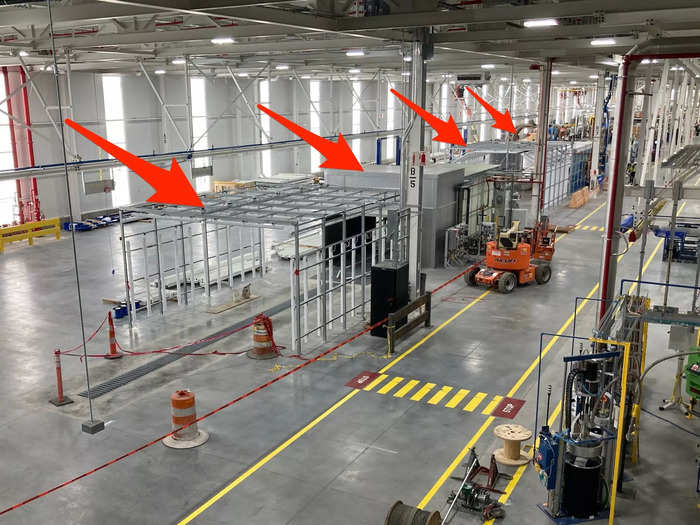

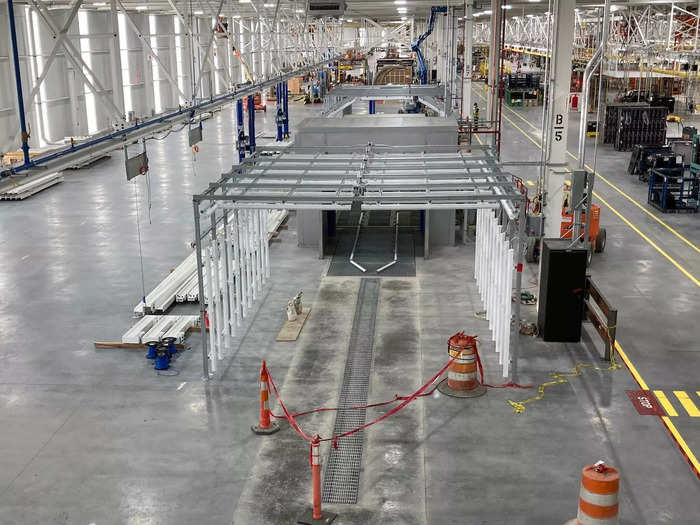

This big open area will eventually become the staging area for parts.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

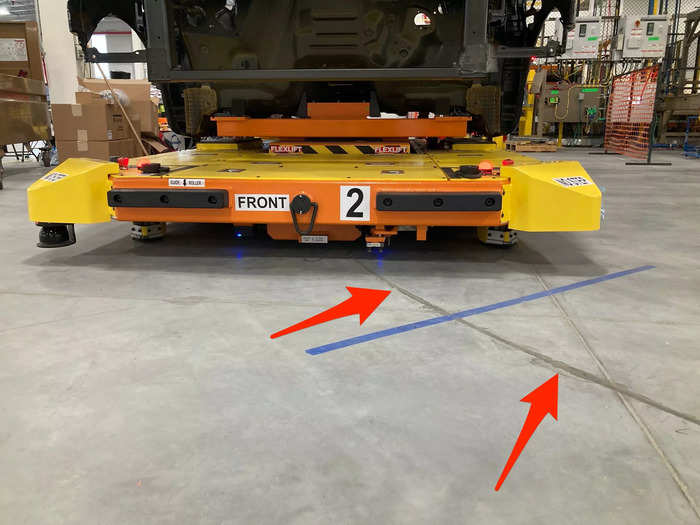

Partly-built vehicles will move through the factory floor on autonomous electric sleds.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

The sleds follow a magnetic track glued into the floor and can sense when a person crosses in front of them.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

Each sled has a built-in lift to bring parts to a comfortable height for any given worker or task.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

When the sleds are stopped at a station, they gather energy through charging points scattered along their route.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

In a conventional plant, the entire assembly line is connected and moves at the same speed. But these sleds can move at different speeds, allowing for more flexibility, Ford says.

The traditional F-150 assembly line.

Carlos Osorio/AP

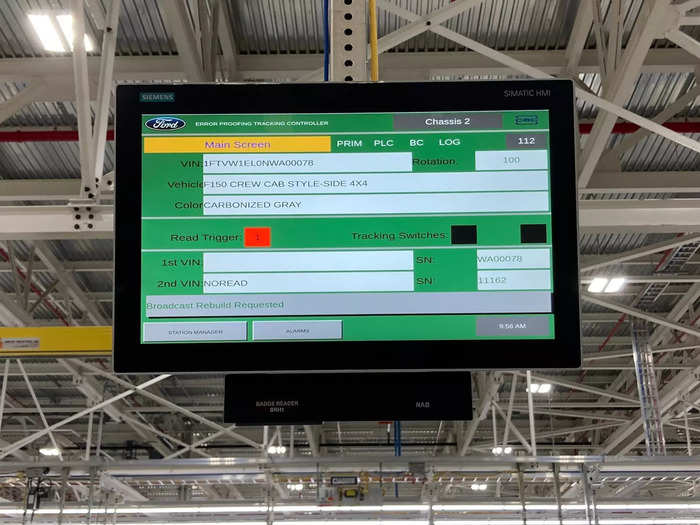

Each station has a computer that knows what configuration of truck is up next and tells the worker what they need to do. The vehicle won’t move down the line until the right bolts are fastened and other tasks are completed.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

That screen will also notify workers of any changes to production or other updates.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

The plant is outfitted with electric tools that sense not only torque, but also strip-outs and cross-threads.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

Some more advanced pieces of equipment can shoot in multiple bolts at once, saving workers time and helping them get to hard-to-reach spots, like inside the bed.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

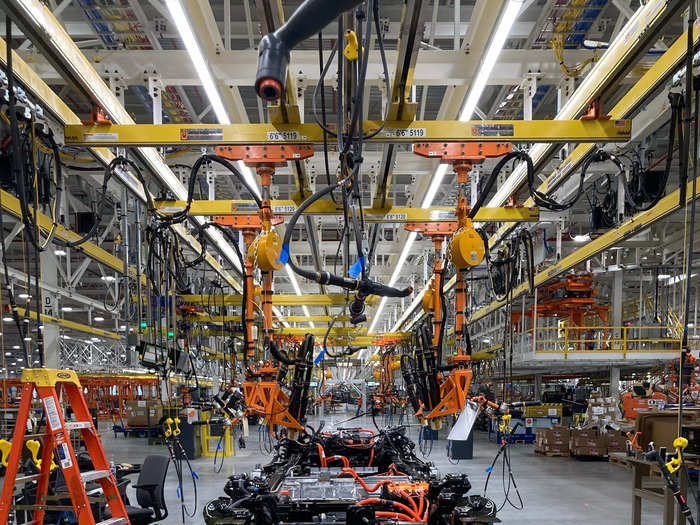

What you immediately notice about the plant is that it feels open and airy since so much equipment is up off the ground.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

On the other side of the building from where the bodies arrive is the chassis shop, where frames are built up with suspension and other components.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

These giant robots pick up a frame and a battery pack and put them together.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

Later on, a massive scissor lift drops down, picks up a cab and bed, and plops it down onto a chassis. From there, the nearly completed truck moves onto the final stages of assembly.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

Some of the last things to go on and in the vehicle are the wheels and fluids.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

This tool tightens down all of a wheel's lug nuts at once.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

At this station, a robotic arm presses down on the truck.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

This is how Ford calibrates the truck's onboard scales, which will measure how much is in the bed for more accurate estimates of battery range.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

At the end of the line, a truck rolls through a series of final quality checks.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

There's an automated vehicle inspection booth that uses dozens of cameras to check for any missing or incorrect parts.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

Then workers do a visual inspection under bright lights.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

Here's where the water tests happen.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

Then there's one final visual inspection.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

The pickups will make one last stop at a charging station to fill up their batteries before heading out the door.

Ford Rouge Electric Vehicle Center.

Tim Levin/Insider

READ MORE ARTICLES ON

Popular Right Now

Popular Keywords

Advertisement