American just received its 46th Airbus A321neo jet. Here's how the airline's popular aircraft is assembled in Alabama from start to finish.

Taylor Rains

- American Airlines celebrated its 50th US-made Airbus jet with a video series showing the assembly of its A321neo.

- The videos show how the aircraft sections are attached, how the interior is assembled, and how the plane is painted.

The Airbus A321neo has soared in popularity among airlines across the industry, becoming a common pick for both domestic and transatlantic routes.

The jet has proven to be a highly efficient aircraft connecting low-demand city pairs at a lower operating cost, and carriers are eager to get it into their fleet.

Source: Insider

As of November 2021, there are 7,776 orders for the A320neo family aircraft from carriers like Delta, Spirit, and JetBlue, with the planemaker delivering a total of 199 A321neos in 2021.

Source: Airbus, FlightRadar24

While most eyes are on the final delivery of the popular narrowbody, one airline has pulled back the curtain to show how the aircraft is assembled in Mobile, Alabama, Airbus' only US plant.

American Airlines recently received its 50th US-made A320 family plane from the $600 million Alabama factory. The aircraft is an A321neo and joined the 45-strong fleet in November 2021.

Source: The Points Guy

The A321neo was first introduced into American's fleet in 2019 and has since become a workhorse for the Dallas/Fort Worth-based carrier flying many transcontinental routes, as well as to Hawaii and Alaska.

To commemorate the occasion, the airline released a five-part video series documenting each phase of the jet’s assembly, giving aviation enthusiasts a behind-the-scenes look from start to finish.

Source: American Airlines

The A321neo has four main components that are manufactured before being shipped to the US, including the front fuselage from St. Nazaire, France…

Source: American Airlines

…the rear fuselage from Hamburg, Germany…

Source: American Airlines

…the tail from Stade, Germany…

Source: American Airlines

and the wings from Broughton, Wales.

Source: American Airlines

All components, including four sets of the fuselage, are loaded onto a large cargo ship that journeys across the Atlantic to Mobile, which is situated on the Gulf of Mexico.

Source: American Airlines

The trek, which starts in St. Nazaire, takes 13 days and covers 4,511 miles.

Source: American Airlines

Once in port, the parts are loaded onto a barge and transported down the Mobile River to the Final Assembly Line (FAL) where workers begin the process of connecting the front and rear fuselage pieces.

Source: American Airlines

However, before going to the FAL, the sections go to a transshipment hangar where they are inspected.

Source: Insider

Airbus' Mobile facility is located between the two runways at decommissioned Air Force base, Brookley Field, which is about four miles from the harbor.

Source: New York Times

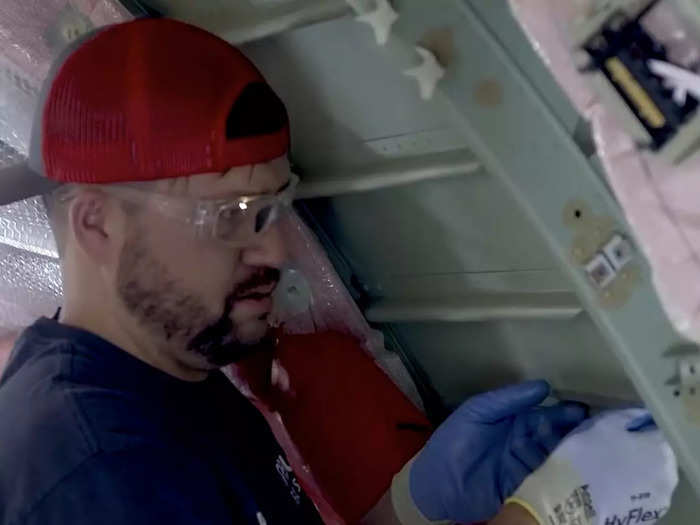

Many of the employees at the plant have experience working on airplanes either for the military or for a private company but are still required to undergo months of rigorous training.

Source: New York Times

To ensure the two fuselage pieces are precisely connected, the workers use special hand-held rulers to determine the "proper fastening position."

Source: American Airlines

They also use the "Fuselage Positioning System" to find the best fit for each piece.

Source: American Airlines

The joining process requires one day of pre-drilling, which includes creating 3,000 rivets each 4.8 millimeters in diameter.

Source: American Airlines

Once the pre-work is complete, the pieces are separated, cleaned, sealed, and reconnected, with the entire process taking about four hours. The front and rear sections weigh about 12,000 and 16,000 pounds, respectively.

Source: American Airlines

After the fuselage is connected, the result is known as the "cigar" which weighs over 28,000 pounds, it is moved to a different part of the factory where the wings and tail are attached.

Source: American Airlines

The 350-pound wings have sharklets that measure 7.5 feet tall, 5.9 feet wide, and 10.5 feet long. Each wing requires 1,200 rivets to attach to the fuselage, with the entire wingspan totaling 117.5 feet and weighing nine tons.

Source: American Airlines

According to Airbus, the sharklets, paired with the plane's engines, improve the jet's fuel efficiency by 15%.

Source: American Airlines

The A321neo featured in American's docuseries is powered by LEAP-1A engines made by CFM International. However, the plane can also be equipped with Pratt & Whitney's PurePower PW1100G-JM geared turbofan engine.

Source: American Airlines, Aerospace Technology

In conjunction with the wings, the A321neo's tail is also attached. It comes pre-painted in American's livery to protect it during transport and sits 38.6-feet tall once mounted.

Source: American Airlines

Part of the assembly process includes installing the galleys, lavatories, overheads bins, and seats into the fuselage.

Source: American Airlines

The galleys are made with a honeycomb core and a reinforced fiberglass surface. Moreover, the cabin is insulated to protect passengers from noise and extreme temperatures.

Source: American Airlines

Meanwhile, Airbus' Airspace XL overhead bins are installed in the cabin. According to the airline, passengers onboard its A321neos are on average 8% more satisfied than on jets without the larger bins.

Specifically, the Airspace XL boasts 60% more bag space than the smaller models, with the capability to carry eight carry-ons vertically. According to Airbus, the product "emphasizes cabin spaciousness and stowability."

Source: Airbus

One of the most important pieces of the cabin is the seats. American configures its A321neo cabin with 196 seats, including 20 in first class, 47 in main cabin extra, and 129 in the main cabin.

Source: American Airlines

The first class seats each weigh approximately 81 pounds, while main cabin seats weigh about 32 pounds.

Source: American Airlines

The final step in the process is the plane's paint job. According to American, it takes 200 rolls of masking tape, 125 gallons of paint, and eight days to complete the livery, which requires 16 different colors.

Source: American Airlines

Primer is used to prevent corrosion and helps in the application of each coat of paint.

Source: American Airlines

Once the jet is completely assembled, it is sent to Airbus' delivery center where airlines pick up their new planes.

Airbus' assembly in Mobile is the end of the A321neo's global process. The plane has components hailing from dozens of factories and countries across the world, which has become a common practice among large manufacturers.

Source: New York Times

These corporations find it advantageous to assemble the final product in the market where it is sold, according to the New York Times. In this case, piecing together the A321neo in Alabama and delivering it to US-based American Airlines.

Source: New York Times

According to Airbus, the company has a goal to produce its aircraft in the US for no more than it costs to assemble in Europe. It is able to achieve this, in part, by hiring non-unionized American workers and paying them less than their European counterparts, reported the Times.

Source: New York Times

Moreover, Airbus executives hope US airlines will be more inclined to buy planes assembled in their home country as the planemaker continues to compete with rival Boeing.

Source: New York Times

READ MORE ARTICLES ON

Popular Right Now

Popular Keywords

Advertisement