Inside The Brooklyn Factory That Makes Suits For America's Most Powerful Men [PHOTOS]

On Varet Street in East Williamsburg, a 100-year-old brick building houses the last unionized men’s clothing factory in New York City with more than 100 employees.

![Inside The Brooklyn Factory That Makes Suits For America's Most Powerful Men [PHOTOS]](/_next/image?url=https%3A%2F%2Fstaticbiassets.in%2Fthumb%2Fmsid-38825717%2Cwidth-700%2Cheight-525%2Cimgsize-1221217%2Fon-varet-street-in-east-williamsburg-a-100-year-old-brick-building-houses-the-last-unionized-mens-clothing-factory-in-new-york-city-with-more-than-100-employees-.jpg&w=3840&q=75)

The city was once an epicenter of apparel manufacturing, with more than 3,000 clothing factories rooted here. During the 1970s, fast and low-cost labor abroad forced U.S. companies to ditch the “Made in the USA” label for cheaper alternatives.

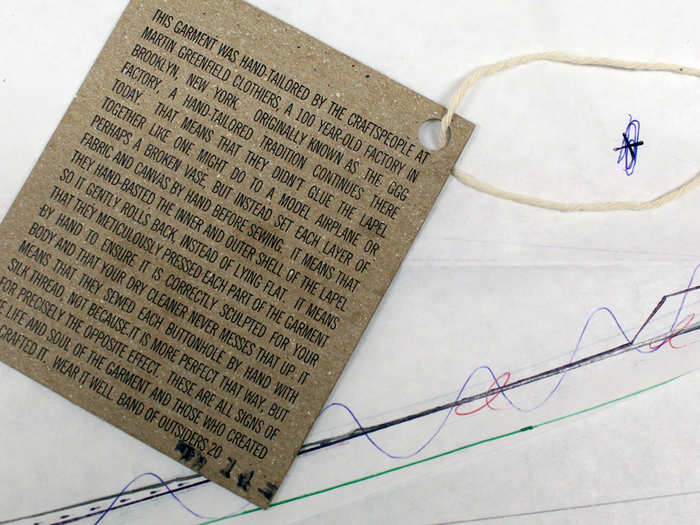

Today, 97.5% of apparel sold in America is made outside the U.S. Martin Greenfield Clothiers is the exception — a company thriving by doing things the old-fashioned way, and employing people rather than machines.

And that's just the way the owner, Martin, likes it. He's worked in this factory since 1947.

Every suit produced here is handmade, the culmination of 108 different operations done over the course of 16 labor hours. One person hand-sews the button holes, while another stitches the lining into the jacket sleeves.

Tod Greenfield (right), Martin’s son and the factory’s co-owner, estimates that 100 employees handle each suit from the time it’s a pile of fabric until it’s a completed garment. Each of the 120 workers is responsible for a handful of tasks.

Pedro Sanchez, an employee of 29 years, presses the jackets in between operations. In mass-production facilities, the suit won’t be pressed until it’s finished, which makes it lie stiff on the body. Here, a suit takes on a man’s complicated geometric shape from the very start.

Celeste Suarez says when she started 22 years ago, she "did everything.” Now, she carefully inspects each jacket before it leaves the production floor for the tailor’s shop.

Of course, Martin Greenfield’s could save boatloads of money and time by mechanizing many of these tasks. But to do so would be to sacrifice the quality of a bespoke, made-to-measure suit.

No two people are alike. When a tailor makes a suit by hand, he has endless flexibility to customize the garment to every square inch of its owner.

The client might have one shoulder that sags, or he might desire a New York City-themed lining. A special order doesn't disrupt the assembly line, because every order is special.

This grants flexibility to the customer as well as the manufacturer. Martin Greenfield’s can produce a greater variety of suits because it doesn’t have to reprogram the machines for every varying fit or style. “Humans are adaptable,” Tod Greenfield says.

For such high quality, clients pay a premium — about $2,500 a suit. The co-owners keep costs down by not buying advertising, which would increase the markup of the suits. They rely on word of mouth instead.

“Most clothing is made strictly for profit. If it can be made somewhere else for 3% cheaper, most entities would move to save the 3%,” Tod says. “We’re not motivated that way. Clothes-making is in my father’s blood.”

At age 14, Martin and his parents, two sisters, and brother were taken from their home in what was then Czechoslovakia and delivered to Auschwitz. At the concentration camp, he worked in the alteration shop, washing clothes and mending officers’ shirts.

Greenfield lost his whole immediate family in the Holocaust. After being liberated from the camp in 1945, he came to the U.S. and found work as a floor boy at GGG Clothes. He worked his way up from blind stitcher to fitter to supervisor, and 30 years later, bought the factory.

At age 86, he comes to work six days a week and has his hands on every garment — examining, pressing, and expediting it between stations. “I love the work,” Martin says. “I lost my family, but now I have this family.”

His dedication has caught the attention of five U.S. presidents, the last two NYPD commissioners, and megawatt celebrities including Frank Sinatra, Paul Newman, Michael Jackson, James Spader, and Leonardo DiCaprio. All have sported Martin Greenfield suits.

The wood-paneled walls of his office are lined with autographed headshots and letters from his celebrity clients. Mayor Michael Bloomberg sent a personalized R.S.V.P. to Martin's belated bar mitzvah (he celebrated at age 80, since the Nazis prevented him from having one as a teen).

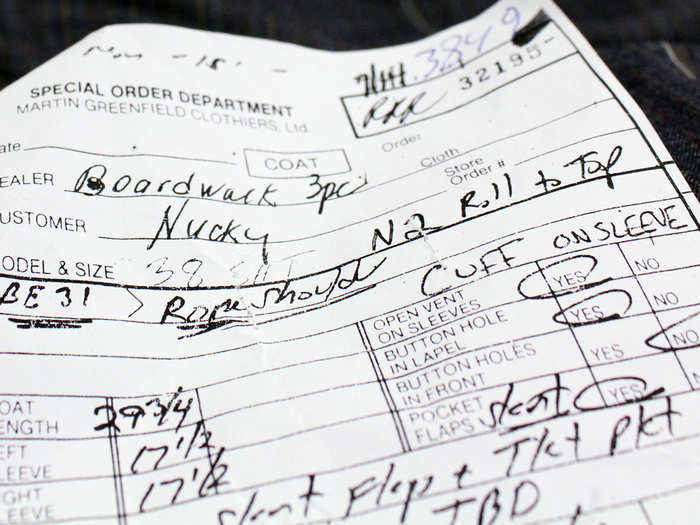

The factory has made more than 600 suits for 200 characters on the HBO period drama “Boardwalk Empire,” Emmy-nominated for its costume design. The order slips list the characters’ names, like Steve Buscemi’s “Nucky.”

Brands dig the customized, Americana vibe, too. Martin Greenfield's supplies Band of Outsiders, Rag & Bones, Freemans Sporting Club, and Brooks Brothers' premium Golden Fleece line.

So how does a company that relies on nearly extinct manufacturing practices — and pays its employees a decent living — continue to grow on a tree-lined block in Brooklyn?

Tod attributes their success to a recent resurgence in consumers wanting to know where their goods come from, whether it’s food, craft beer, or a three-piece suit.

Ten years ago, no one knew who made their suits or how they were made. They bought the label based on the ads that spoke to them," Tod says. "Today, they ask, 'what makes this suit special?'

In a label-obsessed culture, more shoppers are foregoing Gucci’s luxury suits and J. Crew’s more wallet-friendly options for the authentic American craftsmanship and transparency of a Martin Greenfield suit.

They see it happen everyday in the fitting room, where one client — who recently bought his first Martin Greenfield suit — has returned to stock his closet. “They fit beautifully,” he says, eyeing himself in the mirror. “There’s no place like it.”

Now see where your food comes from.

Popular Right Now

Advertisement