- Home

- stock market

- Markets

- FROM DUST TO BARS: The Complete Story Of How Gold Is Mined And Refined

FROM DUST TO BARS: The Complete Story Of How Gold Is Mined And Refined

Carletonville, South Africa, is home to the world's deepest mine. Called TuaTona, it stretches 2.4 mi into the earth.

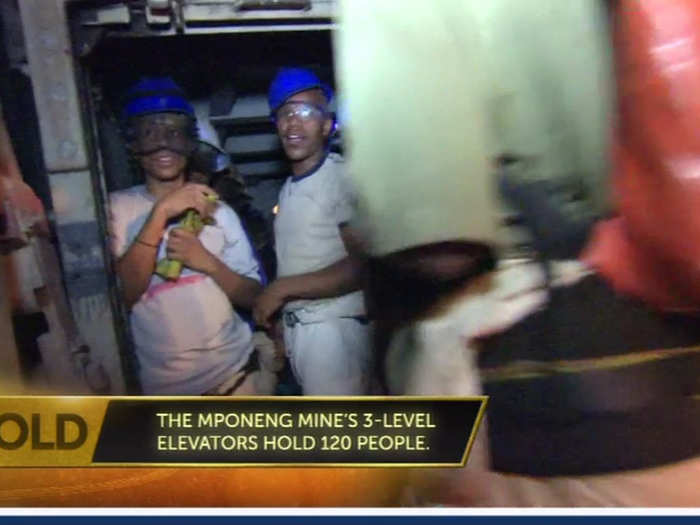

Workers have to ride two elevators to get down to the bottom. The first elevator stretches 8,400 feet, making it one of the longest elevators in the world.

Without its cooling system, the mine would reach more than 150 degrees Fahrenheit (65.5 degrees Celsius).

About 74 miles of track allow workers to traverse the mine.

Workers are constantly wary of seismic activity and methane gas.

Here they can be seen probing the mine's walls for ore.

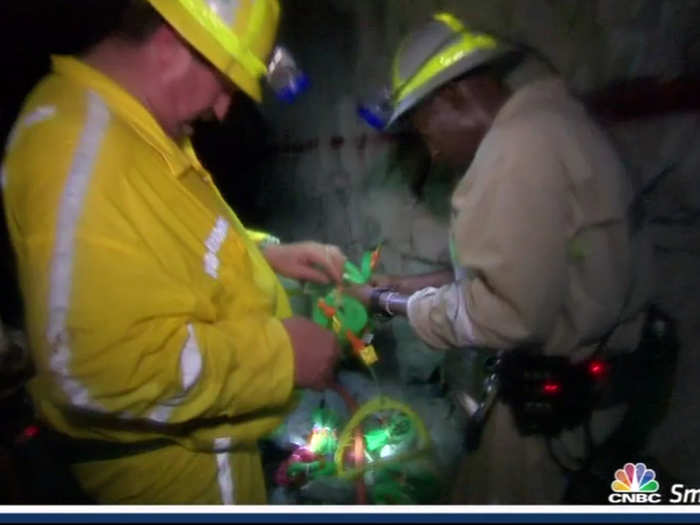

Others prepare to blow away rock with dynamite.

Jumbo drilling rigs and tractors clear up to 5,000 metric tons of earth per day.

Machines cart gold up to the surface, where a sieve filters out gold particles.

Those particles are smelted to gold bars of approximately 90 percent purity on site.

The mine produces these rough gold bars, and ships them off site to be purified.

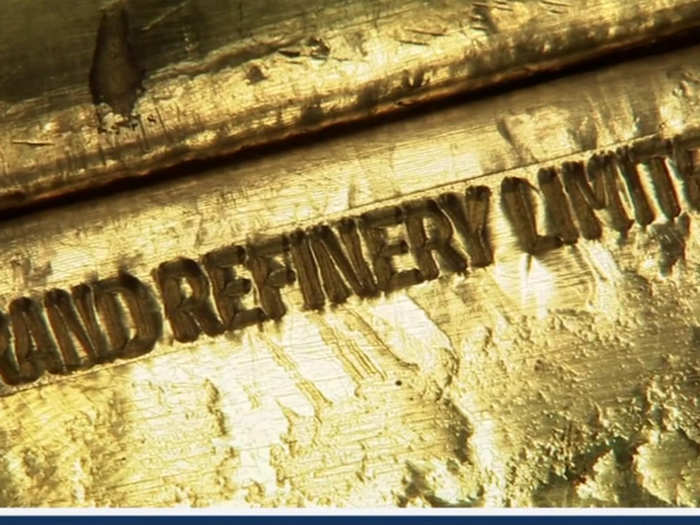

Rough bars from mines all over the world end up at places like the Rand Refinery, which has refined 50,000 tons of gold—or nearly one third of the gold mined globally—since 1920/

The refinery begins with rough bars.

First, they are sent to be cleaned and dried.

Then a conveyor belt transports them to a weigh station.

The refinery determines the chemical purity before melting down the gold.

Which is filtered to 99 percent purity...

And then poured into a crucible.

Workers use the crucible to transport the liquid gold, and pour it into a mold.

Once slightly solid, the bars are removed from the mold.

And then the bars cool down in water.

Each gold bar is stamped with a unique identification number...

And a seal showing where it was refined.

Finally, workers hit bars with a hammer.

Each gold bar weighs about 26 pounds each.

Now check out the countries with the world's largest gold reserves...

Popular Right Now

Popular Keywords

Advertisement