- Home

- slideshows

- miscellaneous

- I went behind the scenes at Chick-fil-A to see how its famous chicken sandwich is made - and I learned the whole process is really a race against the clock

I went behind the scenes at Chick-fil-A to see how its famous chicken sandwich is made - and I learned the whole process is really a race against the clock

Truett Cathy founded Chick-fil-A on his secret recipe to success — the recipe for what's now the chain's Original Chicken Sandwich.

He modeled the cooking process off of the way his mother would fry chicken at home: She would put a lid over the stove to create a sort of pressure cooker, which allowed the chicken to cook more quickly and evenly.

Cathy took this covered cooking idea and brought it to Henny Penny — a food-equipment manufacturing company — and came up with a special pressure fryer that's now used in all Chick-fil-A locations. I got to see how it works! But more on that later.

Source: Henny Penny

I don't ever remember having to wait more than five minutes for my food at Chick-fil-A. Admittedly, that has definitely raised some questions in my mind about freshness.

But, there's actually a reason for that super short wait time at the chain that wants us all to "Eat More Chikin" — they've got timing down to a science.

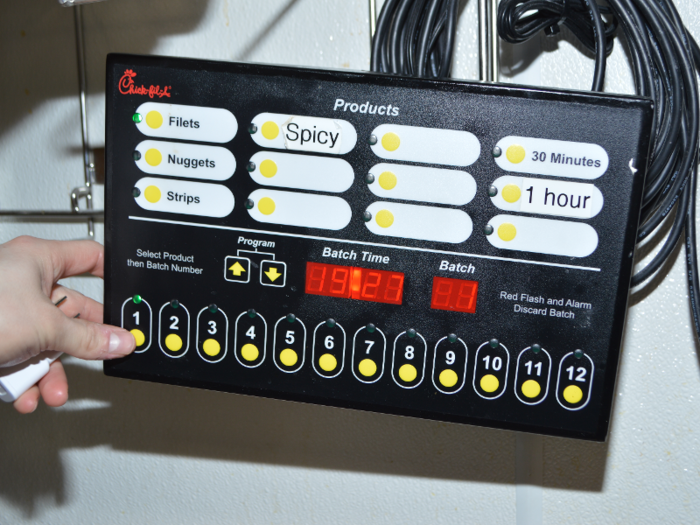

The entire Chick-fil-A chain practices the Lean Process, a way to reduce waste and increase value to guests, according to the company. Restaurants use a Kanban system to keep timing on track — a Kanban is anything that triggers employees to make more food, like these empty bins getting passed back to the prep station.

On the more technical side, restaurants use an algorithm that keeps track of daily production and sales numbers. It predicts how much business the particular location will do the next day and uses that information to tell employees how many fillets per bin should be breaded, reducing the amount that goes to waste.

But the process of building the no-frills sandwich starts way before the algorithm kicks in.

Boxes of frozen chicken breasts arrive by truck once a day, six days a week. They go into the walk-in freezer — along with the chain's top selling waffle fries and other cuts of meat — and wait their turn to thaw in a separate refrigerator.

Source: Business Insider

Since there's no heat added to help the chicken thaw, the process takes a full 24 hours. So, you won't be eating chicken for dinner that came out of the freezer that morning.

After completely thawing, the breasts are carefully inspected to make sure they all meet company standards. That means no tears down the middle or imperfections at all.

Then they're brought into the kitchen, where the real fun begins.

The first stop is the breading station. Inside the giant metal box are several bins with all the necessities for breading fillets ...

... including a set of instructions.

The employee manning the station hand-fillets each chicken breast by running their thumb up the seam. The team calls the smooth side of a chicken breast the crown, and the rough side — or the side with the seam — is the heel.

Sometimes sub-par chicken pieces or breasts will make their way to the breading station. In that case, the breader will catch them and set them aside as waste.

After the ones that make the cut are filleted properly, breaders hold onto the chicken by the tail — two at a time — and dunk them in the milk and egg wash just once.

Then it's time for the flour coater. Both fillets get laid in the coater bin and buried in the flour mixture until they're no longer visible.

Then — and this is a crucial part of the process, according to Chick-fil-A team members — the person breading needs to put all their weight into pressing down on the fillets. That means heels come off the ground, and hands press down hard on the chicken.

Fillets get flipped over, covered, and pressed down again for an even coating. Then they go into one of two bins dedicated to the original chicken, and move onto the fryer.

If you've ever worked with breading and flour, you now it can get clumpy after a few rounds of dunking. When this happens, the team member sifts the flour, removes any clumpy pieces, and replenishes the stock as needed.

Coated, raw fillets get loaded onto a multi-tiered basket, ready for a quick dip in the pressure fryer.

Naturally, the fillets aren't the exact same thickness all around. To ensure an even cook, employees place the tail of the fillet pointing inward toward the center of the fryer.

The coils that heat the peanut oil run around the walls of the fryer, so the outside edges are where the oil is hottest — that's why the thickest part of the fillet is better off on the outskirts of the basket.

The lid is closed and a timer is set. It takes exactly four minutes to cook the chicken for this sandwich.

Look at that perfectly golden fry!

Once the chicken is cooked, the basket is lifted out of the pressure fryer and rests in the notches of this funneling contraption. The notches allow employees to quickly tip the basket over without dropping any of the chicken on the ground.

It all gets funneled into another bin and then brought over to the assembling station, where they're on the clock.

Breaded and cooked fillets can only sit in a bin, unassembled, for 20 minutes. If the timer runs out, the fillets get pulled. This is where the algorithm is helpful — it tries to ensure there aren't more fillets being made than there are being ordered.

Fear not waste haters. Unassembled fillets — which means the cooked pieces of chicken that haven't yet touched so much as a single leaf of lettuce — can be re-purposed.

Once that 20 minutes is up, the heart of the sandwich gets put into a refrigerator, cooled down, and then cut up and put into soup.

But let's get back to the chicken that does make it into the sandwiches.

Assemblers watch the orders come in on a screen like this and prep the sandwiches for the shoot. This is when the magic happens, folks.

First thing's first: The buns need to be buttered. This small metal contraption holds liquid butter and rolls it right onto the bun.

One swipe of each side of the bun across the roller leaves you with a perfectly buttered bun — unless it's the first of the day, then you need to swipe once for the roller to pick up the butter, then again to get it on the bun.

Then, into the toaster they go!

It's important the toaster be set to the right temperature, or you'll end up with buns that are only half toasted, or even burnt — those get thrown away.

Up next: Pickles!

The pickles go through a vetting process. Anything that looks like this, is torn at all, or is larger than a dime just doesn't make the cut.

Chick-fil-A's policy is two pickles per sandwich. However, they'll make an exception if the pickles are small and will add a third.

Pickle placement is also meticulous. Overlapping too much, or setting them down off-center like this, is a no-go.

The pickles have to be touching, but not quite overlapping, and need to be placed in a way that allows them to cover the maximum amount of surface area. This placement is ideal.

After the pickles have been carefully placed on the heel of the bun — yep, they use "heel" and "crown" to describe the buns as well — it's time for the chicken.

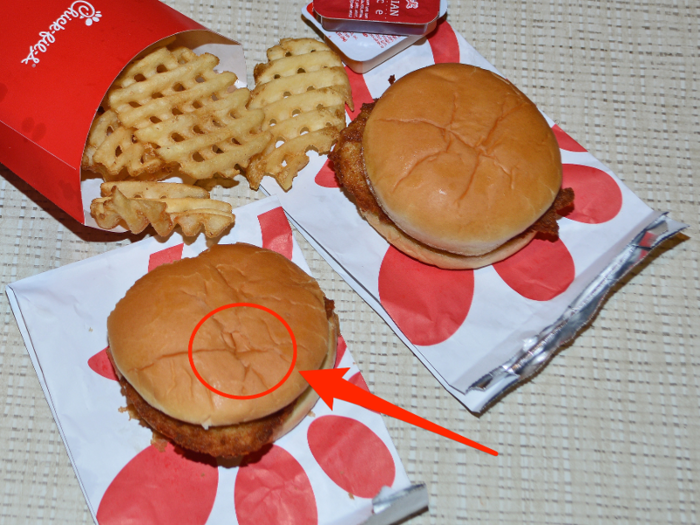

There's a rule of three corners at Chick-fil-A. The three corners of the fillet have to hit three points on the edge of the bun like a triangle.

Top it off with the crown of the bun and the sandwich is complete. But wait! It's still got to make it to the customer.

This is where Chick-fil-A's custom aluminum bags come in, and where I tried my hand at bagging the sandwiches.

To be completely honest, this was the hardest part of the process for so many reasons. First of all, putting the sandwich in the bag is a lot tougher than it looks.

Opening the bag is an art of its own. Adam Hall, a team member at the Fulton Street location, told me to hold the packet open with my non-dominant hand and insert the sandwich with my dominant hand. Sounds easy, but it's not.

The sandwich has to be pushed all the way to the bottom of the packet, but you have to be careful not to smush the bun. Of course, I smushed the bun.

Then it needs to be folded. Adam drew a dotted line on one packet as an example. But again, it's harder than it looks.

Mine wasn't as perfect as Adam's, but he said it was alright for a first-timer. That sounds like a win to me!

Once the sandwich is in the bag, folded immaculately, of course, it's ready to go onto the chute, into a customer's bag, and ultimately, their stomach.

Assembled sandwiches on the chute are on the clock for five minutes. Anything that doesn't get sold when that timer runs out is thrown away — luckily for me, mine made it back to the office for lunch.

Popular Right Now

Popular Keywords

Advertisement