During flight, the exterior paint or coating of any aircraft can get worn down from friction caused by weather, dust, bugs, and the normal movement of flight surfaces.

The F-35A also has several panels that are frequently removed or opened on the flight line for routine maintenance, and there are more than 5,000 fasteners that keep body panels in place. All of these, when worn, can potentially limit the jets stealth capabilities.

The fabrication flight team inspects and evaluates the jets' coatings, seams and panels after each flight, looking for anything that could lead to an increased radar signature, recording any damage and prioritizing repairs across the wing's fleet.

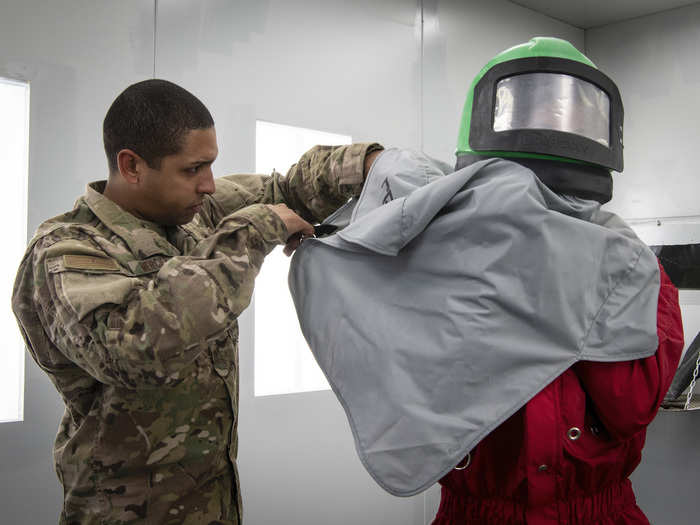

At work in their shop, the LO technicians work in a team, hunched intently over a long table full of composite panels and rubber seals. They wear masks and gloves, and look more like sculptors or painters than fabricators.

The old, heavy equipment used for cutting, pounding, bending and joining sheet metal for F-16 skins, lines the walls behind them, mostly unused. The machines a reminder of the difference between fourth- and fifth-generation technology.

"I like that its detail oriented," said Staff Sgt. Brandon Ladson, a low observable journeyman. "All the work that you put in really shows. Any mistake you make, every good thing you do, it all shows in the final product."

The active-duty 388th FW and Air Force Reserve 419th FW are the Air Force's only combat-capable F-35 units, working side-by-side, maintaining the jets in a Total Force partnership that utilizes the strengths of both components.