Keurig's cold drink maker was a wildly complicated, multi-million dollar piece of tech - and that's why it flopped

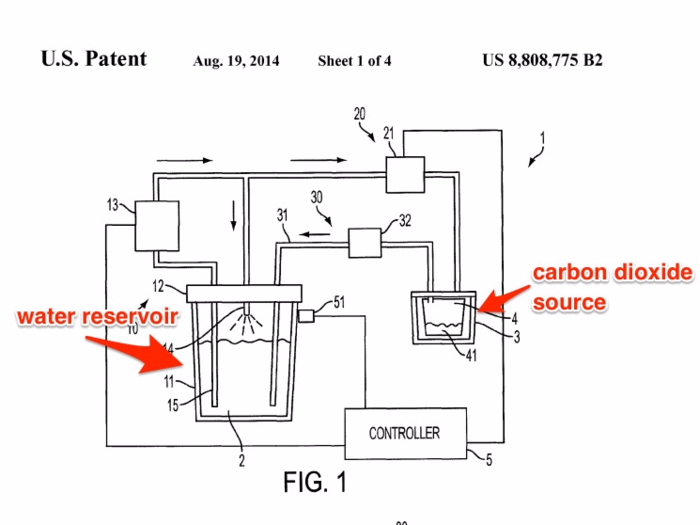

It starts with a chiller.

The cold water then flows into the pod.

As the chiller does its job, a small amount of water is brought to the cartridge chamber, where the flavor pod is located.

The drawings in this August, 2014 patent by Keurig's Thomas Novak, Ross Packard, Peter Peterson and Shawn Gulla for a "Method and apparatus for cartridge-based carbonation of beverages" are not the exact schematics for the Keurig Kold machine. However, they do show the tech that underpins it, as water moves from one chamber to another.

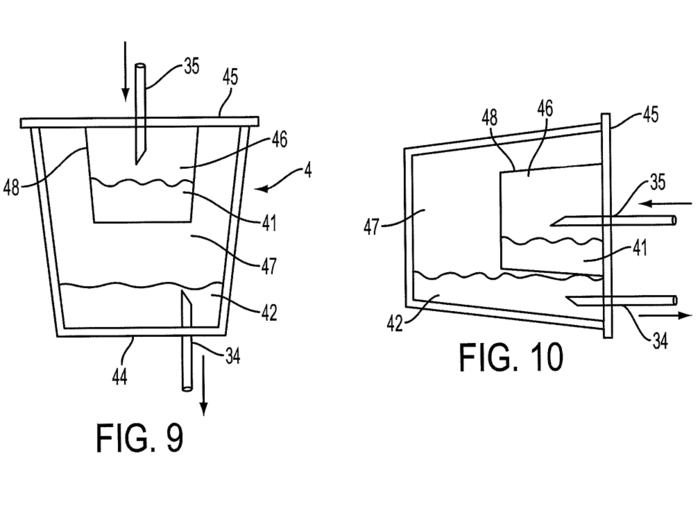

The carbonation comes from "beads" in the upper chamber.

The flavor pod is divided into the two chambers. One contains beads that are made with a blend of minerals – primarily aluminum silicate – with tiny porous spaces that hold carbon dioxide captive until they're exposed to water. Keurig calls them "Karbonator" beads.

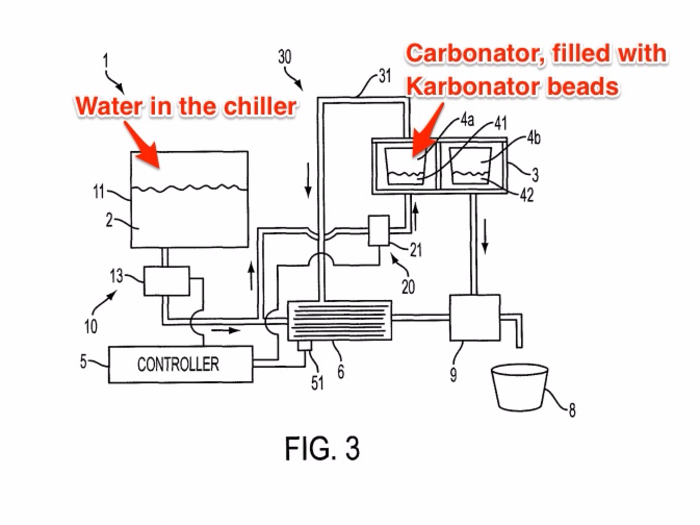

The second chamber contains the beverage syrup, which comes into play later.

Once the system registers the water in the chiller has reached the optimum temperature of approximately 37 degrees, the Keurig Kold releases the small amount of water into the top of the pod, wetting the beads and releasing the carbon dioxide.

...but it doesn't end there...

The released carbon dioxide then has to travel back into the chiller to carbonate the water.

(Again, patent illustrations are not exact replicas of the Kold — this one provides an illustration of the Keurig-patented process through which "liquid is carbonated in a single pass through a carbonator," with arrows showing the path water takes to become carbonated.)

Mixed, and ready to drink.

At this point, the system's mixer expels the pod's syrup just as the carbonated water is being released, producing two separate streams that combine to make the beverage. The timing and volume are key, as they allow for the consistent blend of carbon dioxide, water, and syrup in the drink, without requiring mixing after the fact.

"We knew the machine needed the ability to perfectly dose and mix the beverage so that we could deliver a consistent beverage time after time," DuLong told Business Insider. "We knew from experience with the hot system, that the only way to attract partners — people whose reputations in their beverage brand — was to guarantee that consistency time and time again.”

All of this occurs in about 90 seconds. Then, the pod — including the beads — are discarded, and the user is left with a 39 degree glass of soda, seltzer, or cocktail mixer.

Here's why it failed.

Some of the harshest complaints from Kold users seem to be a result of this whole process. They said the Kold was too big, took a long time to cool down before its ready to use, and that it could be very noisy.

Because of the interconnected system used by the Kold, Keurig was unable to solve these problems. As a result, the device that once promised to be the future of the brand was instead simply a flop, despite the years of research and millions of dollars invested in the machine.

"We view our initial Kold system launch as a pioneering execution," Keurig said on Tuesday in a statement. "We learned a lot — including that consumers are willing to embrace the concept of a system that delivers fresh-made, cold beverages in the home — and we'll build our learnings into future beverage systems."

Popular Right Now

Advertisement