How a small family-owned company in New Jersey has been manufacturing cool for more than 100 years

In an unsuspecting town, on an unsuspecting street, far away from the glitz and glamour of their Manhattan boutique, hides Schott's corporate office and factory.

Walk past the reception area, down the halls lined with offices and conference rooms, make a left, and you've reached the factory floor, where about 100 union employees work tirelessly to pump out 200 leather jackets and other pieces of apparel each day.

Jason Schott, the great-grandson of Irving Schott (one of the original "Schott Bros.") runs the company as COO, along with Roz Schott, his mother, who serves as president, and Steve Colin, his uncle, who serves as CEO.

Schott has been making leather jackets and wool apparel for more than 100 years — and now, as the rocker look comes back into style, they're more popular than ever. "We saw a significant increase in 2014, and it's been consistently hot since then," Jennifer Goldszer, director of public relations at Schott NYC, told Business Insider earlier this month.

It all started in 1913, when pattern-maker Irving Schott decided to strike out on his own and sell raincoats door-to-door. Schott struck gold when in 1928 he decided to put the still-very-new zipper on a leather jacket, creating the very first of what would later be called a motorcycle jacket.

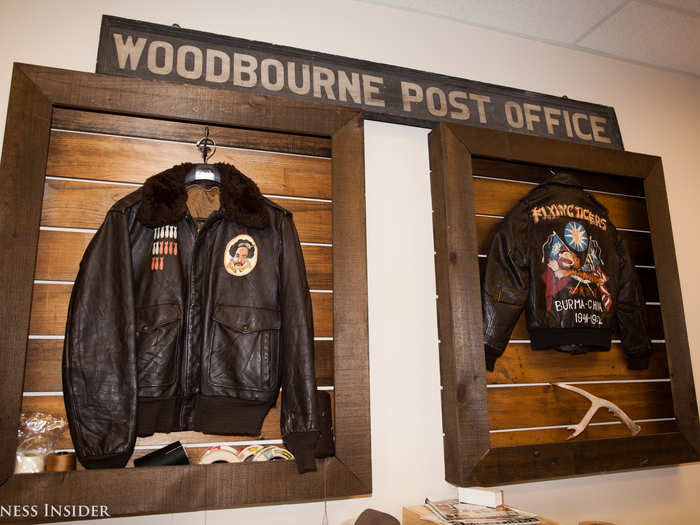

It was sold nationwide through a deal with Harley Davidson dealerships and Beck motorcycle parts sales magazines. From there, Schott scored several lucrative contracts, creating peacoats for the navy and bomber jackets and motorcycle jackets for police officers. The factory moved to New Jersey to expand.

Some of those early examples still exist in the Schott archive, like this NYC Transit Police jacket.

The leather jacket picked up more cultural meaning in the 1950s. The company grabbed mainstream attention when Marlon Brando donned a motorcycle jacket in the 1953 movie "The Wild One", effectively putting Schott on the map.

The leather jacket became symbolic of the bad boy and rebel, and students would be banned from wearing them at school.

That stigma was reinforced in the '70s and '80s, when The Ramones wore Schott jackets as part of their signature punk look.

Modern stars have embraced the signature cool look of the Schott leather jacket. Rihanna, Kanye West, Matthew McConaughey, and Jay Z have all been photographed wearing a Schott brand jacket. Schott told us that the company never actively seeks these endorsements, but that the stars appreciate Schott for being a "cool underground brand". Schott admits that they'd like to be "a little less underground" at times.

The brand has now developed a loyal cult following through their commitment to their customers and to making only minimal changes to their styles year over year. Their annual factory sale on the first Saturday in December regularly has people lining up around the block to get a chance to snag a coat at a lower price. Schott does not regularly run sales at other times of the year.

Schott has recently branched out to boutique retail stores, opening locations in New York City and Los Angeles, as well as six in Europe and another six in Japan. More are planned all over the world.

Jason Schott told us that the company places a special emphasis on production, since many of their items are both designed and manufactured in-house. "For us, it always started from the production side of things," Schott told us.

My great-grandfather used to wear this tie clip that said YCDBSOYA: You can't do business sitting on your a--," Jason Schott told us. "That really is the family motto.

When constructing the jackets, it all starts with the leather. Schott uses full-grain cowhide leather, which is the highest quality leather you can find. It uses the full grain of the hide for enhanced strength.

Schott mostly uses cowhide, but some special jackets are made with sheepskin or other leathers. Many of the women's jackets use lambskin, which is somewhat softer.

Each jacket has its own pattern and its own stencil for the leather and lining pieces to be cut out of.

The lining will be sketched out on paper, then overlaid on the material, and cut together using a pair of shears.

For leather, the process is somewhat different. The leather cutters cut the leather pieces into the shapes for the jackets using a knife and a polymer plastic stencil.

The cutting is extremely precise work, and new leather cutters must prove themselves by cutting hundreds of smaller pieces, gradually working their way up. They're trained to use as much of the hide as possible, making every nook and cranny part of the jacket.

That's no issue for John, who has been a Schott leather cutter for 43 years. "All my life," he said.

For smaller pieces — think the belt loops on a motorcycle jacket — a machine can cut many at a time.

After being cut, the pieces are then bundled together with similar pieces and taken to the place in the factory where they will be stitched together.

At this point, the pieces are also checked for uniformity.

The pieces are then stitched together. Some of them are delicate, like the zippers in the sleeves.

And others less so, like the tag in a pea coat. The pea coat is still one of Schott's best sellers. "Every year, once it gets cold, people want their pea coats," Schott told us.

Some of the machines are extremely old, and when they break, a part must be custom-made to fix it. This one is nearly 100 years old and stitches a very delicate part of the jacket — the belt loops. Only the mechanic is allowed to operate it.

The stitching creates a seam, which is then glued and hammered down to create a smooth inside.

The jackets are stitched inside-out, and a small hole is left in the sleeve.

They are pulled right side in using a metal spike, which creates a perfect edge.

Any ornamentation for the jacket is then added, including Schott's signature star detailing on the epaulets. A machine operated by a foot petal punches the stars into the leather.

The hole is then sewn up, and the jacket is sent to quality control.

Every jacket must be inspected to ensure perfection.

After inspection, the jackets are tagged, bagged, and sent to the shipping area.

At this stage, some jackets could also be put in this industrial tumble washer with stones before being tagged. Tumbling around with the stones will break the leather in faster, allowing the jacket to conform to the owner's body more quickly.

The jackets are then stored in the warehouse, waiting to be shipped to the Schott retail store, wholesalers, or customers' front doors.

As many as 30 to 40 styles of jackets are being assembled on the factory floor at any one time. "At least half of our styles will remain in our collection from year to year," Schott told us. "We've got a good handful of styles that have been in our collection for 30 years. It's building that long-term relationship with our customers, because we plan to be here for a while longer."

Popular Right Now

Popular Keywords

Advertisement