- Home

- slideshows

- miscellaneous

- Check out the $230 million factory in North Carolina where Honda builds its private jet

Check out the $230 million factory in North Carolina where Honda builds its private jet

We visited the home of HondaJet in early February. We were fortunate that the day we selected for our visit was extremely mild, even by local standards. Immediately upon arrival, we were reminded that this was unlike any other Honda facility.

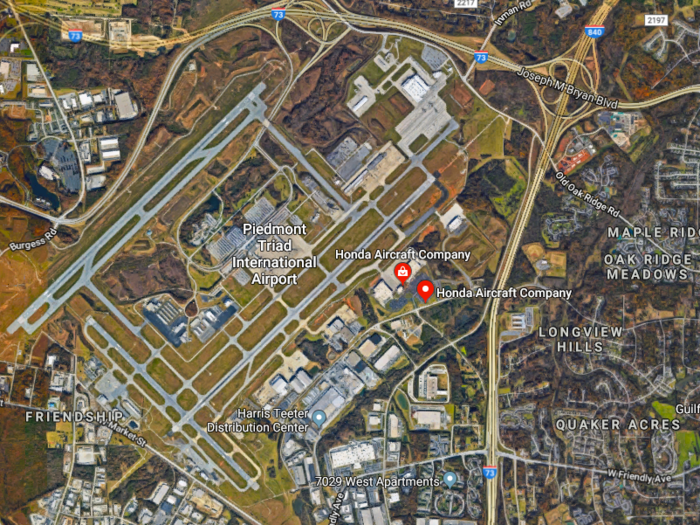

This sprawling 133-acre campus is the result of Honda's $230 million investment into its North Carolina home.

The campus is adjacent to Piedmont Triad International Airport just a few miles northwest of downtown Greensboro.

Waiting for us on the apron was a new HondaJet Elite, the main reason for our trip.

The HondaJet Elite certainly impressed us with its stylish design, innovative tech, and comfortable ride.

Following the test flight, we got a tour of the campus where 1,500 people work.

Inside the main administrative building there's mock-up of HondaJet along with the company's other high-profile products, such as a Gold Wing motorcycle and...

... an NSX supercar.

There's also a miniature architectural model of the campus.

Next up, the main assembly facility.

We had to wear safety goggles.

It is in this room where the Honda Jet comes together.

The jet begins the process as carbon composite fuselage shells.

The fuselages are supplied by GKN Aerospace.

Next, the wings, vertical stabilizer, and landing gear are fitted to the fuselage.

The Honda/GE HF120 turbofan engines are then installed on pylons above the wing. The engines are made in nearby Burlington, North Carolina.

Work is also conducted on the inside of the carbon composite fuselage.

There are jets lined up along the walls of the production facility in various stages of completion.

Every aircraft is meticulously hand assembled.

A nearly completed aircraft emerges at the end of the production line.

After leaving the main production facility, the jet is painted and fitted with a custom interior.

The final product is presented to the customer at HondaJet's cavernous delivery center.

It comes complete with a luxurious reception area and even a turntable so the customer can view his or her new jet for every angle.

Next, take a tour of the inside of the HondaJet Elite.

Popular Right Now

Advertisement