The largest diamond factory in the US is leading a revolution in the jewelry industry

Diamonds that come into the factory are uncut and rough. These rough yellow diamonds are about to be measured.

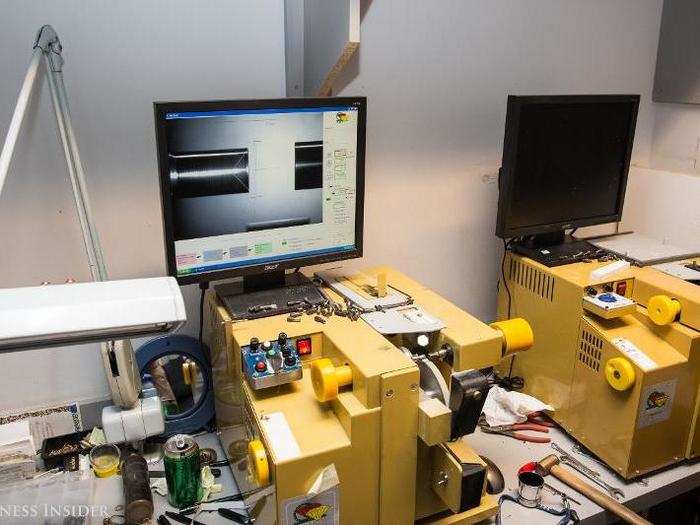

To get the most value out of a rough stone, the pieces are scanned, creating a 3D version that is analyzed closely to determine if, and where, the stone should be cut before being shaped. The workers consider several different factors, including the stone's flaws and weight.

Some stones are cut to create two separate pieces. How they cut the diamond is also determined by the market — what's selling, and what's not.

According to Keeney, most millennials are keeping it traditional. The round and princess cut diamonds are the best sellers, although they do see micro trends, such as rose gold bands and heart-shaped diamonds, having a moment.

The quality and price of a diamond is determined by the four C's: cut, color, clarity, and carat weight.

Cut: There are various cut options to choose from when it comes to shaping a diamond, including round, princess, cushion, emerald, and more. Cut refers to both the amount of light a diamond refracts as a result of its proportions, and to the shape of the stone.

Color: This refers to the "whiteness" of a diamond. The less color, the more valuable it might be.

Clarity: Clarity is determined by how many tiny scratches are within the diamond.

Carat weight: The weight of the diamond once it's cut and polished.

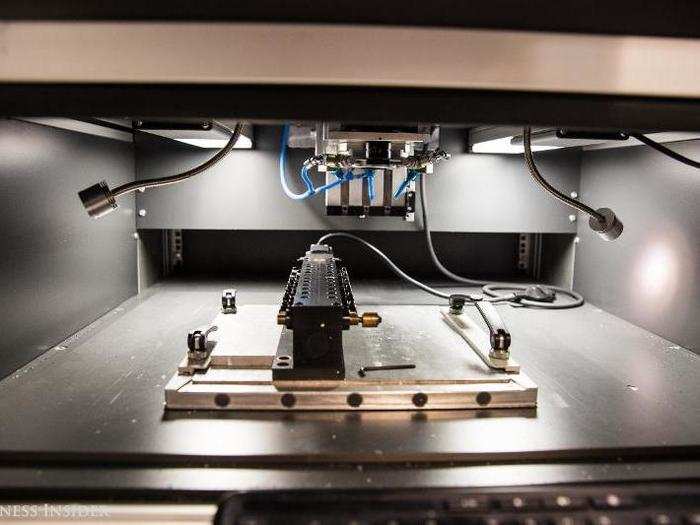

Once it's determined that a stone needs to be cut, it's sent to the laser cutter, which creates a precise cut. This process can take up to three hours, and is technically difficult to pull off correctly. The man behind all of Ritani's diamonds has studied continuously for over five years with the manufacturer of the machine in Antwerp, and in the US.

Next, the cut diamonds go a work station. Here, a craftsman who specializes in specific diamond cuts works with the stone to create a masterpiece.

Many of the craftsmen have been working at this factory for 40 years or more.

Diamonds are placed within the "tang," a device that holds the diamond as it's being polished.

The tang is then placed above a spinning disc that is coated in diamond dust, which cuts the stone.

The craftsman either places weight with his hands or uses block weights to push the diamond in the tang onto the spinning diamond dust, creating the facets of the diamond that make it sparkle.

Diamond cutting can range from a few weeks to several months, based on the size, cut, and overall polishing process. One round diamond can have up to 58 facets, creating what Ritani calls "maximum sparkle."

The largest, most precious rare diamonds can take up to a year to cut.

After cutting and polishing is done, the diamond makes its way to these machines, which polish the girdle of the diamond and ensure uniform roundness.

After the final polish, the diamond is thoroughly examined to GIA (Gemological Institute of America) standards before being independently certified.

The stone is then ready to be set in a ring.

Ritani's online shopping aspect extends into the store. IPads on the counter tell you the exact specs of the ring you've ordered.

An Apple TV is also provided so that customers can compare the diamonds' size, cut, clarity and price to make a final decision.

Recently, Ritani sold a three-stone ring with three individual extremely rare colored stones for close to $3 million.

Popular Right Now

Advertisement